Global Cold Gas Spray Coatings Market has valued at USD 1.24 billion in 2022 and is anticipated to project robust growth in the forecast period with a CAGR of 4.25% through 2028. In the realm of advanced surface engineering technologies, Cold Gas Spray (CGS) coatings have emerged as a transformative force, offering unique advantages across various industries

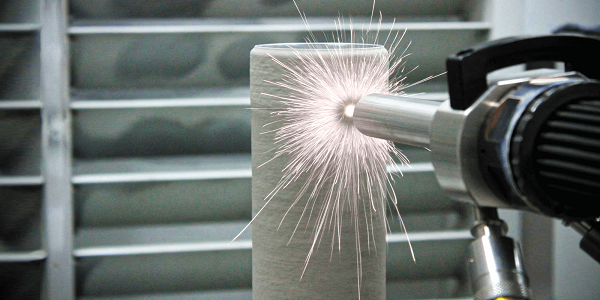

Cold Gas Spray (also known as Cold Spray or Supersonic Particle Deposition) is an innovative coating process that involves spraying finely powdered coating materials at supersonic speeds onto a substrate. Unlike traditional thermal spray methods, CGS operates at lower temperatures, mitigating thermal stress on materials. This technique preserves the unique properties of the coating material and substrate, resulting in enhanced performance and durability.Cold Gas Spray Coatings Market stands at the forefront of technological innovation, offering a versatile solution for diverse industries. As advancements continue, addressing challenges and leveraging collaborative efforts will be crucial for unlocking the full potential of CGS coatings. The market’s evolution promises not only enhanced material performance but also a more sustainable and efficient future for various industrial applications.

Key Market Drivers-Cold Gas Spray Coatings Market

- Demand in Aerospace Industry The aerospace industry, with its relentless pursuit of technological advancements, has become a primary catalyst for the remarkable growth of the global cold gas spray coatings market. This innovative coating technology has found its wings in aerospace applications, proving to be a game-changer in enhancing the performance, durability, and efficiency of critical aircraft components.

- Electronics Industry Growth The rapid expansion of the electronics industry has become a driving force behind the remarkable surge in demand for cold gas spray coatings. This sophisticated coating technology has found a burgeoning market within the electronics sector, where the pursuit of miniaturization, enhanced performance, and robust protection of electronic components is paramount.In the ever-evolving landscape of electronic devices, cold gas spray coatings have carved a niche for themselves. From printed circuit boards (PCBs) to delicate electronic components, the demand for coatings that enhance conductivity, protect against corrosion and ensure longevity is driving the widespread adoption of cold gas spray technology.The electronics industry is synonymous with the constant quest for smaller, more powerful devices. Cold gas spray coatings offer a solution by providing a protective layer that not only shields components from environmental factors but also enhances their conductivity. This is especially crucial in the era of miniaturization, where every nanometer matters in the performance of electronic devices.Electronic components often operate in harsh environments where exposure to moisture, chemicals, and varying temperatures can lead to corrosion. Cold gas spray coatings, with their exceptional corrosion resistance properties, act as a barrier, ensuring the longevity and reliability of electronic components in diverse conditions.

- Manufacturing Efficiency In the realm of manufacturing, where efficiency is a cornerstone, Cold Gas Spray (CGS) coatings have emerged as a transformative technology. This sophisticated coating method is increasingly becoming a driving force behind the global push for enhanced manufacturing efficiency.Cold Gas Spray coatings find diverse applications across the manufacturing spectrum. From the repair and protection of industrial equipment to the coating of critical components, this technology is proving instrumental in streamlining processes and extending the operational life of machinery.Manufacturers are increasingly turning to CGS coatings to extend the operational life of their equipment. By applying durable and wear-resistant coatings to critical components, industries can enhance the reliability of machinery, resulting in fewer breakdowns and increased productivity.One of the primary ways in which CGS coatings contribute to manufacturing efficiency is through surface restoration. Worn-out or damaged components can be efficiently restored, eliminating the need for costly replacements. Additionally, the protective nature of CGS coatings shields equipment from wear, corrosion, and abrasion, ensuring a longer lifespan and reducing downtime for maintenance.

Download FREE Sample Report @ https://www.techsciresearch.com/sample-report.aspx?cid=21160

Aerospace engineers are increasingly turning to cold gas spray coatings for a range of applications. From turbine blades and engine components to structural elements, the demand for lightweight yet robust coatings is paramount. Cold gas spray technology offers a unique solution by providing a protective layer that is not only durable but also resistant to extreme temperatures and harsh environmental conditions.One of the key drivers of cold gas spray coatings in the aerospace sector is the emphasis on weight reduction. As the industry grapples with the challenge of improving fuel efficiency and reducing emissions, every ounce saved becomes critical. Cold gas spray coatings offer a lightweight alternative without compromising on strength and protective capabilities, contributing significantly to the overall fuel efficiency of aircraft.Aerospace components are exposed to a variety of environmental factors, including high-altitude conditions, moisture, and varying temperatures. Cold gas spray coatings, with their corrosion-resistant properties, act as a shield, protecting vital components from deterioration. This is particularly crucial in enhancing the lifespan of aircraft components and reducing maintenance costs.Key Players-Cold Gas Spray Coatings Market

- ASB IndustriesBodycote plcFlame Spray Technologies BVPlasma Giken Co., Ltd.VRC Metal SystemsCenterLine (Windsor) LimitedWWG Engineering Pte. Ltd.Praxair S.T. Technology, Inc.Impact Innovations GmbHConcurrent Technologies Corporation

Key Challenges-Cold Gas Spray Coatings Market

- Technological Complexity Cold Gas Spray coatings involve a precise and intricate process wherein finely powdered coating materials are accelerated to supersonic speeds and deposited onto a substrate. While the technology offers unparalleled benefits, including reduced thermal stress and superior coating adhesion, its intricacies pose challenges for widespread adoption.

- Product Overview 1.1. Market Definition1.2. Scope of the Market1.2.1. Markets Covered1.2.2. Years Considered for Study1.2.3. Key Market Segmentations

Download FREE Sample Report @ https://www.techsciresearch.com/sample-report.aspx?cid=21160

The complexity of CGS technology requires a meticulous integration process into existing manufacturing workflows. Optimizing the technology for specific applications demands a deep understanding of the intricacies involved.Implementing CGS coatings necessitates a skilled workforce capable of operating and maintaining the specialized equipment. The training curve for technicians and operators introduces challenges, particularly in industries where traditional coating methods are prevalent.The absence of standardized processes for CGS coatings can lead to variability in outcomes. Establishing industry-wide standards is crucial for ensuring consistency and interoperability across diverse applications. You may also read:[2028] Traffic Road Marking Coatings Market Update, Overview, Data, ForecastIron Oxide Pigments Market [2028]: A Deep Dive into the Latest Market Trends, Market Segmentation[2028] Oil and Gas Corrosion Protection Market Future, Outlook, Outlook, SegmentsIndia Ethanol Market | [2029] Exploring Growth, Potential, and Future, Trends Table of Content-Cold Gas Spray Coatings Market- Research Methodology

2.1. Objective of the Study2.2. Baseline Methodology2.3. Key Industry Partners2.4. Major Association and Secondary Applications2.5. Forecasting Methodology2.6. Data Triangulation & Validation2.7. Assumptions and Limitations

- Executive Summary

3.1. Overview of the Market3.2. Overview of Key Market Segmentations3.3. Overview of Key Market Players3.4. Overview of Key Regions/Countries3.5. Overview of Market Drivers, Challenges, Trends

- Impact of COVID-19 on Global Cold Gas Spray Coatings MarketGlobal Cold Gas Spray Coatings Market Outlook

5.1. Market Size & Forecast5.1.1. By Value and Volume5.2. Market Share & Forecast5.2.1. By Technology (High Pressure, Low Pressure)5.2.2. By End Use (Automotive, Aerospace, Electrical and Electronics, Oil and Gas, Medical, Utility, Others)5.2.3. By Region5.2.4. By Company (2022)5.3. Market Map

- Asia Pacific Cold Gas Spray Coatings Market Outlook

6.1. Market Size & Forecast6.1.1. By Value and Volume6.2. Market Share & Forecast6.2.1. By Technology6.2.2. By End Use6.2.3. By Country6.3. Asia Pacific: Country Analysis6.3.1. China Cold Gas Spray Coatings Market Outlook6.3.1.1. Market Size & Forecast6.3.1.1.1. By Value and Volume6.3.1.2. Market Share & Forecast6.3.1.2.1. By Technology6.3.1.2.2. By End Use6.3.2. India Cold Gas Spray Coatings Market Outlook6.3.2.1. Market Size & Forecast6.3.2.1.1. By Value and Volume6.3.2.2. Market Share & Forecast6.3.2.2.1. By Technology6.3.2.2.2. By End Use6.3.3. Australia Cold Gas Spray Coatings Market Outlook6.3.3.1. Market Size & Forecast6.3.3.1.1. By Value and Volume6.3.3.2. Market Share & Forecast6.3.3.2.1. By Technology6.3.3.2.2. By End Use6.3.4. Japan Cold Gas Spray Coatings Market Outlook6.3.4.1. Market Size & Forecast6.3.4.1.1. By Value and Volume6.3.4.2. Market Share & Forecast6.3.4.2.1. By Technology6.3.4.2.2. By End Use6.3.5. South Korea Cold Gas Spray Coatings Market Outlook6.3.5.1. Market Size & Forecast6.3.5.1.1. By Value and Volume6.3.5.2. Market Share & Forecast6.3.5.2.1. By Technology6.3.5.2.2. By End Use