The Global Automotive Rubber Molded Components Market plays a critical role in the automotive industry, providing essential parts that contribute to vehicle safety, performance, and overall functionality. This market includes a wide array of products such as seals, gaskets, hoses, bushings, and various other components that are crucial in automotive manufacturing.

As vehicles become more advanced, the demand for high-quality rubber molded components has grown, driven by the need for enhanced durability, improved performance, and compliance with stringent safety and environmental standards. This report delves into the complexities of the market, examining the factors driving its growth, the challenges it faces, and the opportunities that lie ahead.

Automotive Rubber Molded Components Market Overview

Market Size and Growth

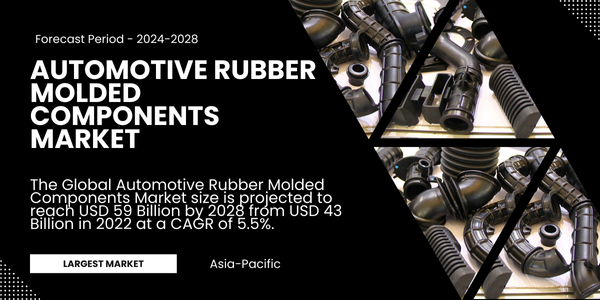

The Global Automotive Rubber Molded Components Market was valued at USD 43 billion in 2022, according to TechSci Research. The market is projected to grow at a compound annual growth rate (CAGR) of 5.5% from 2024 to 2028, reflecting robust demand across the automotive sector.

Browse over XX market data Figures spread through XX Pages and an in-depth TOC on the “Global Automotive Rubber Molded Components Market” @ https://www.techsciresearch.com/report/automotive-rubber-molded-components-market/3645.html

This growth is underpinned by several critical factors, including the rapid expansion of the automotive industry, especially in emerging markets, and the increasing focus on vehicle efficiency and sustainability. As automakers continue to innovate, the need for more advanced, reliable, and environmentally friendly rubber molded components will intensify, driving further market expansion.

Importance of Rubber Molded Components

Rubber molded components are indispensable in modern vehicles, performing functions that are crucial to the overall operation and longevity of the vehicle. These components are found in nearly every part of a vehicle, from the engine and transmission to the suspension and electrical systems. They serve to seal and protect various systems from environmental factors such as moisture, dust, and extreme temperatures, which can cause wear and tear over time.

Key Automotive Rubber Molded Components Market Drivers

Increased Automotive Production

The increasing production of automobiles globally is a major driver of the Global Automotive Rubber Molded Components Market. With rising disposable incomes, urbanization, and improving infrastructure in many parts of the world, the demand for both passenger and commercial vehicles has surged. This increase in vehicle production necessitates a higher volume of rubber-molded components, which are used in nearly every aspect of vehicle manufacturing.

Advancements in Rubber Molding Technologies

Technological advancements in rubber molding have revolutionized the production of automotive components, leading to significant improvements in efficiency, precision, and quality. As a result, rubber-molded components are becoming increasingly capable of meeting the rigorous demands of modern vehicles, contributing to enhanced performance and longevity.

Demand for Lightweight Materials

The automotive industry is under increasing pressure to reduce vehicle weight in order to improve fuel efficiency and meet stringent emissions regulations. Lightweighting has become a key focus for automakers, as reducing the overall weight of a vehicle directly impacts its fuel consumption and carbon emissions. Rubber molded components, which are inherently lightweight, offer significant advantages in this regard. By replacing heavier materials like metal or plastic with advanced rubber compounds, automakers can achieve weight reductions without compromising on durability or performance.

Shift Towards Green Vehicles

The global automotive industry is increasingly moving towards green vehicles, driven by a combination of regulatory pressures, environmental concerns, and changing consumer preferences. Rubber molded components that are eco-friendly, such as those made from recycled or bio-based materials, are gaining traction in this context. These components help manufacturers meet sustainability goals while maintaining the performance and reliability expected by consumers.

Automotive Rubber Molded Components Market Segmentation

By Component Type

The Global Automotive Rubber Molded Components Market can be segmented by component type, with each segment playing a distinct role in vehicle manufacturing:

-

Seals and Gaskets: These components are vital for maintaining the integrity of various vehicle systems by preventing the leakage of fluids and gases. In engines, for example, gaskets ensure that oil and coolant remain within the designated channels, preventing contamination and potential engine damage. The demand for high-performance seals and gaskets is particularly strong in advanced automotive applications, such as turbocharged engines and hybrid powertrains, where maintaining pressure and thermal stability is critical.

-

Hoses: Automotive hoses are used to transport fluids such as coolant, fuel, and brake fluid throughout the vehicle. They must withstand high temperatures, pressure, and exposure to chemicals without degrading. The development of advanced rubber compounds has enhanced the durability and flexibility of hoses, making them more resistant to the harsh conditions they encounter in the automotive environment.

-

Bushings: Bushings play a key role in vehicle suspension systems by absorbing shocks and vibrations, thereby improving ride comfort and reducing wear on other components. They are typically made from elastomeric materials that provide the necessary flexibility and damping properties.

-

Others: This category includes a wide range of other rubber molded components, such as O-rings, grommets, bellows, and plugs. These components are often small but play critical roles in various vehicle systems, such as ensuring airtight seals in air conditioning units or protecting electrical wiring from moisture and abrasion. The versatility of rubber as a material allows for the production of components that can meet a wide variety of automotive needs.

By Vehicle Type

The market can also be segmented by vehicle type, with different types of vehicles requiring different rubber molded components:

-

Passenger Cars: This is the largest segment in the market, driven by the high production and sales of passenger cars globally. The increasing demand for comfort, safety, and fuel efficiency in passenger cars is driving the adoption of advanced rubber molded components that can meet these requirements.

-

Commercial Vehicles: This segment includes trucks, buses, and other vehicles used for commercial purposes. These vehicles often operate in more demanding environments and require components that can withstand heavy loads, long operating hours, and harsh conditions. As a result, the demand for durable and high-performance rubber molded components is particularly strong in this segment.

-

Electric and Hybrid Vehicles: The electric and hybrid vehicle segment is growing rapidly as consumers and manufacturers alike shift towards more sustainable transportation options. These vehicles have unique engineering requirements, including specialized rubber components that can handle the specific demands of electric powertrains and battery systems. The growing adoption of EVs and HEVs is expected to drive significant demand for rubber molded components tailored to these applications.

By Region

The market is geographically segmented into several regions, each with its own dynamics and growth opportunities:

-

North America: North America is a mature market with a well-established automotive industry. The region’s focus on innovation, particularly in the areas of electric vehicles and autonomous driving, is driving demand for advanced rubber molded components. Additionally, the presence of major automakers and a strong supply chain infrastructure supports the growth of the market.

-

Europe: Europe is known for its strict regulatory standards, particularly concerning safety and environmental sustainability. The European market places a strong emphasis on the use of high-quality, eco-friendly materials in automotive manufacturing. This focus on sustainability, coupled with the region’s leadership in electric vehicle adoption, is expected to drive demand for advanced rubber molded components.

-

Asia-Pacific: The Asia-Pacific region is the largest and fastest-growing market for automotive rubber molded components. The rapid expansion of the automotive industry in countries like China, India, and Japan is fueling demand for these components. Additionally, the region’s growing focus on electric vehicles and environmental sustainability is expected to further boost the market.

-

Latin America: Latin America is an emerging market with significant growth potential, particularly in countries like Brazil and Mexico. The region’s expanding automotive industry, coupled with increasing investments in infrastructure and manufacturing, is expected to drive demand for rubber molded components.

-

Middle East and Africa: The Middle East and Africa represent a smaller but steadily growing market for automotive rubber molded components. The region’s increasing demand for vehicles, driven by economic growth and urbanization, is expected to support market expansion. Additionally, the growing focus on sustainability and environmental responsibility in the region is likely to drive demand for eco-friendly rubber molded components.

Challenges in the Automotive Rubber Molded Components Market

Volatility of Raw Material Prices

One of the most significant challenges facing the Global Automotive Rubber Molded Components Market is the volatility of raw material prices, particularly rubber. Rubber prices are influenced by a variety of factors, including weather conditions in major rubber-producing regions, supply-demand dynamics, geopolitical events, and fluctuations in currency exchange rates.

Download Free Sample Report @ https://www.techsciresearch.com/sample-report.aspx?cid=3645

Customers can also request 10% free customization on this report.

For example, natural disasters such as floods or droughts can disrupt rubber production, leading to supply shortages and price spikes. Similarly, trade tensions or changes in tariffs can impact the cost of importing rubber, further contributing to price volatility. This unpredictability poses a challenge for manufacturers, who must manage costs while ensuring the consistent quality and availability of their products.

Regulatory Compliance and Environmental Standards

Navigating the complex landscape of regulatory compliance and environmental standards is another major challenge for manufacturers in the automotive rubber molded components market. Different regions have different safety, emissions, and quality regulations, each requiring rigorous testing, certification, and quality control measures.

Quality Assurance and Consistency

Maintaining consistent quality and performance across rubber-molded components is critical but challenging. Any variation in quality can lead to product recalls, safety concerns, and damage to a manufacturer’s reputation. Factors such as the raw material composition, molding process parameters, and environmental conditions during manufacturing can all impact the final product’s quality.

Customization and Design Flexibility

The demand for customization and design flexibility is increasing, with automakers seeking tailor-made solutions for specific vehicle design and performance requirements. Developing custom rubber compounds and tooling can be time-consuming and expensive, particularly when production volumes are low. Manufacturers must balance the need for customization with the demands of cost efficiency and scalability to remain competitive in the market.

Supply Chain Complexity

The global supply chain for rubber molded components is complex and susceptible to disruptions. Events such as natural disasters, trade tensions, and pandemics can disrupt the flow of raw materials and finished products, leading to delays and increased costs. Additionally, manufacturers must navigate the complexities of global trade, including tariffs, customs regulations, and transportation logistics, to ensure the timely and cost-effective delivery of their products.

Intense Market Competition

The Global Automotive Rubber Molded Components Market is highly competitive, with numerous suppliers vying for business from automakers. This intense competition exerts pressure on pricing and profit margins, as manufacturers strive to offer high-quality products at competitive prices. To stay ahead of the competition, manufacturers must continuously invest in research and development to create innovative rubber compounds, efficient manufacturing processes, and cost-effective solutions.

Technological Advancements

Electric Vehicles (EVs) and Hybrid Electric Vehicles (HEVs)

The rise of electric vehicles (EVs) and hybrid electric vehicles (HEVs) presents both challenges and opportunities for the Global Automotive Rubber Molded Components Market. Additionally, the lightweighting trend in EVs drives the demand for rubber components that are both lightweight and durable, helping to extend the vehicle’s range. As the adoption of EVs and HEVs grows, manufacturers are developing tailored solutions to meet these specific needs, such as rubber compounds that offer enhanced thermal stability, electrical conductivity, and chemical resistance.

Autonomous Systems and Advanced Driver Assistance Features

The integration of autonomous systems and advanced driver assistance features (ADAS) in vehicles is another area where rubber molded components play a critical role. These systems require highly reliable and precise components to ensure safe and efficient operation. For example, autonomous vehicles rely on a range of sensors, cameras, and other electronic components that require effective sealing and protection from environmental factors. Rubber molded components, such as gaskets, seals, and protective boots, are essential for shielding these sensitive electronics from dust, moisture, and vibration.

Sustainability and Eco-Friendly Materials

The automotive industry’s commitment to sustainability is driving the adoption of eco-friendly rubber materials and production processes. As automakers seek to reduce their environmental footprint, there is growing interest in rubber compounds that are made from recycled materials, bio-based sources, or other sustainable inputs. For example, manufacturers are exploring the use of natural rubber alternatives, such as guayule or dandelion-derived rubber, which offer similar performance characteristics with a lower environmental impact.

Future Prospects

Emerging Markets

The growth of emerging automotive markets, particularly in Asia, Latin America, and Africa, is expected to drive the expansion of the Global Automotive Rubber Molded Components Market. Additionally, governments in these regions are investing in infrastructure and manufacturing capabilities, further supporting the growth of the automotive industry. Manufacturers have the opportunity to tap into these growing markets by expanding their presence, developing products tailored to regional needs, and building strong relationships with local automakers and suppliers.

Innovation in Materials and Manufacturing

The ongoing innovation in materials and manufacturing processes is expected to play a key role in the future growth of the market. Advances in rubber compounds, such as the development of new elastomers with enhanced performance characteristics, are enabling the production of components that are more durable, heat-resistant, and chemically stable.

Collaboration and Partnerships

Collaboration and partnerships between automakers, suppliers, and technology providers will be essential for navigating the challenges and seizing the opportunities in the Global Automotive Rubber Molded Components Market. By working together, industry stakeholders can develop innovative solutions that meet the evolving needs of the automotive industry.

Download Free Sample Report @ https://www.techsciresearch.com/sample-report.aspx?cid=3645

Customers can also request 10% free customization on this report.

For example, collaborations between rubber manufacturers and automakers can lead to the co-development of new rubber compounds that are specifically tailored to the requirements of next-generation vehicles. Additionally, partnerships with technology providers can help manufacturers integrate advanced materials and production processes into their operations, enhancing their competitiveness. These collaborations will also help drive the adoption of new technologies and materials, ensuring the continued growth and development of the market.

Conclusion

The Global Automotive Rubber Molded Components Market is a dynamic and resilient segment of the automotive industry, characterized by continuous growth and innovation. While the market faces challenges such as raw material price volatility, regulatory compliance, and intense competition, it also benefits from several key drivers, including increased vehicle production, technological advancements, and the shift towards green vehicles.

You may also read:

Dehydrated Garlic Market Analysis Growth, Size, and Trends with 7.4% CAGR to {2029}

Desiccated Coconut Powder Market Overview Key Insights, Trends, and [4.2% CAGR] Forecast to 2029

Die-Cast Toys Market Industry Trends USD 1247.66 Million Market Size and Growth Projections Through {{2029}}

Dishwasher Market Forecast USD 22.2 Billion Value and 6.68% CAGR Through [2029]