Global Carbon Fiber Market was valued at USD 7.25 Billion in 2023 and is anticipated to project steady growth in the forecast period with a CAGR of 7.25% through 2029. In recent years, the global carbon fiber market has experienced remarkable growth and transformation, driven by advancements in technology, increasing demand from various industries, and a growing emphasis on lightweight and high-performance materials.

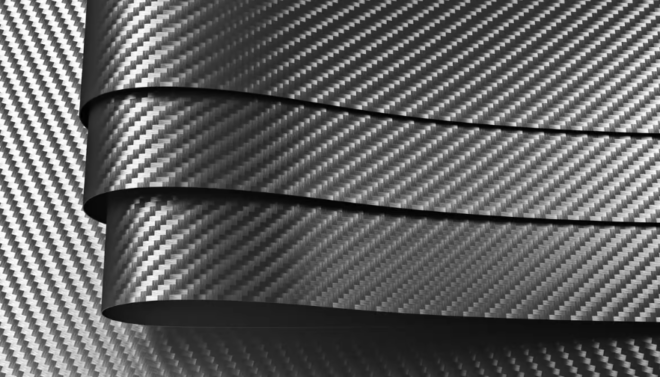

Carbon fiber, renowned for its exceptional strength-to-weight ratio and durability, has become a critical material across multiple sectors, including aerospace, automotive, sports and leisure, wind energy, and more.

In aerospace, carbon fiber is extensively used in aircraft manufacturing to reduce weight and enhance structural integrity. The defense industry also utilizes carbon fiber for various applications due to its strength and versatility. The wind energy sector has embraced carbon fiber for manufacturing turbine blades, as these materials are more efficient and durable in harsh environments.

Carbon fiber’s popularity in sports and leisure products such as bicycles, tennis rackets, and golf clubs has surged due to its ability to enhance performance.

Browse over XX market data Figures spread through XX Pages and an in-depth TOC on the “Global Carbon Fiber Market” @ https://www.techsciresearch.com/report/global-carbon-fibre-market/2712.html

Key Market Drivers

Growing Demand in Automotive and Aerospace Industries is Driving the Global Carbon Fiber Market

Carbon fiber, once a niche material primarily used in high-performance applications, is now witnessing surging demand driven largely by the automotive and aerospace industries. This trend is reshaping the global carbon fiber market landscape, with significant implications for both manufacturers and end-users.

In the automotive sector, the pursuit of lightweighting has emerged as a critical strategy to enhance fuel efficiency, extend range, and reduce emissions. Carbon fiber’s exceptional strength-to-weight ratio makes it an attractive alternative to traditional materials like steel and aluminum. By incorporating carbon fiber-reinforced composites (CFRP) into vehicle components such as chassis, body panels, and interiors, automakers can achieve substantial weight savings without compromising structural integrity or safety. Moreover, stringent regulatory requirements worldwide are driving automakers to adopt lightweight materials to meet fuel economy standards and emission targets. As electric and hybrid vehicles gain prominence, reducing vehicle weight becomes even more crucial for optimizing battery efficiency and performance. This has spurred a growing demand for carbon fiber in the automotive industry, with major manufacturers investing in carbon fiber production capacities to meet escalating market needs.

Similarly, the aerospace industry has been a significant driver of carbon fiber adoption. Aircraft manufacturers are increasingly turning to carbon fiber composites for constructing critical components like fuselages, wings, and interior structures. The aerospace sector values carbon fiber for its strength, stiffness, and fatigue resistance, essential properties for ensuring aircraft safety and performance.

The use of carbon fiber in aircraft contributes to substantial weight reduction, which translates into enhanced fuel efficiency and increased payload capacity. As airlines seek to reduce operating costs and environmental impact, carbon fiber emerges as a compelling solution to achieve these objectives. Furthermore, advancements in carbon fiber technology have enabled the production of larger and more complex aerospace components, facilitating the development of next-generation aircraft designs.

The growing demand for carbon fiber in automotive and aerospace applications has profound implications for the global carbon fiber market. Manufacturers are expanding production capacities and investing in research and development to meet industry-specific requirements and capitalize on emerging opportunities. Moreover, advancements in manufacturing processes have driven down the cost of carbon fiber production, making it more economically viable for mass-market automotive applications.

This cost reduction, coupled with rising consumer preferences for lightweight and high-performance vehicles, is further accelerating the adoption of carbon fiber in the automotive sector. In aerospace, carbon fiber’s role is poised to expand beyond current applications as manufacturers explore novel ways to leverage its properties for advanced aircraft designs and sustainable aviation solutions. The aerospace industry’s commitment to reducing carbon emissions and improving operational efficiency will continue to drive the demand for carbon fiber in the coming years.

Sustainability and Environmental Regulations is Driving the Global Carbon Fiber Market

The shift towards sustainability has become a driving force in shaping industrial practices worldwide. Manufacturers across diverse sectors, including automotive, aerospace, renewable energy, and consumer goods, are increasingly integrating sustainability goals into their operations.

Download Free Sample Report @ https://www.techsciresearch.com/sample-report.aspx?cid=2712

Customers can also request for 10% free customization on this report

Carbon fiber, with its potential to reduce greenhouse gas emissions and energy consumption compared to traditional materials like steel and aluminum, has become a focal point for achieving sustainability targets. The production of carbon fiber involves processes that emit fewer pollutants and consume less energy compared to many other materials. For instance, the manufacturing of carbon fiber composites generally requires lower temperatures and shorter processing times, resulting in reduced carbon footprints. As companies seek to enhance their eco-friendly credentials, the demand for carbon fiber as a sustainable alternative has surged.

In addition to voluntary sustainability initiatives, stringent environmental regulations are compelling industries to adopt cleaner technologies and materials. Governments worldwide are implementing policies to curb carbon emissions and promote the use of eco-friendly materials in manufacturing.

Carbon fiber’s role in reducing vehicle weight and improving fuel efficiency has positioned it favorably amidst tightening automotive emissions standards.

Environmental regulations also influence the choice of materials in the aerospace, construction, and energy sectors. For instance, carbon fiber-reinforced plastics (CFRP) are increasingly employed in aircraft manufacturing to meet stringent emissions targets and noise regulations. In the construction industry, carbon fiber is being explored as a sustainable solution for enhancing structural strength and reducing the environmental impact of buildings.

The confluence of sustainability initiatives and regulatory pressures has propelled the adoption of carbon fiber across a wide range of industries. In automotive manufacturing, lightweight carbon fiber components are instrumental in achieving higher fuel efficiency and reducing vehicle emissions. Major automakers are investing in carbon fiber technologies to develop electric vehicles (EVs) with extended range and improved performance. Similarly, the aerospace industry is embracing carbon fiber composites to reduce aircraft weight and enhance operational efficiency. Carbon fiber’s exceptional strength and corrosion resistance make it ideal for aircraft components, contributing to lower fuel consumption and reduced maintenance costs over the lifespan of an aircraft.

You may also read:

Sealants Market Forecast Evaluating Future Demands and Growth Opportunities

Diesel Particulate Filter Market Robust Growth Expected 7.4% CAGR & USD 23 Billion by 2028

Anti-Lock Braking System Market Forecasted Growth at 8.9% CAGR Through 2028

Automotive Sun Visor Market USD 2.1 Billion Forecast, Size, and Trends

Automotive Engine Valve Market Anticipated Growth USD 24.5 Billion by 2028

Table of Content-Carbon Fiber Market

- Product Overview

1.1. Market Definition

1.2. Scope of the Market

1.2.1. Markets Covered

1.2.2. Years Considered for Study

1.2.3. Key Market Segmentations

- Research Methodology

2.1. Objective of the Study

2.2. Baseline Methodology

2.3. Key Industry Partners

2.4. Major Association and Secondary Sources

2.5. Forecasting Methodology

2.6. Data Triangulation & Validation

2.7. Assumptions and Limitations

- Executive Summary

3.1. Overview of the Market

3.2. Overview of Key Market Segmentations

3.3. Overview of Key Market Players

3.4. Overview of Key Regions/Countries

3.5. Overview of Market Drivers, Challenges, Trends

- Voice of Customer

- Global Carbon Fiber Market Outlook

5.1. Market Size & Forecast

5.1.1. By Value & Volume

5.2. Market Share & Forecast

5.2.1. By Raw Material (Pan-Based, Pitch-Based, Rayon-Based)

5.2.2. By Product Type (Continuous, Long, Short)

5.2.3. By Fiber Type (Virgin, Recycled)

5.2.4. By Modulus (Standard, Intermediate, High)

5.2.5. By Application (Composite, Non-Composite)

5.2.6. By End Use Industry (Automotive, Aerospace & Defense, Wind Energy, Marine, Others)

5.2.7. By Region

5.2.8. By Company (2023)

5.3. Market Map

5.3.1. By Raw Material

5.3.2. By Product Type

5.3.3. By Fiber Type

5.3.4. By Modulus

5.3.5. By Application

5.3.6. By End Use Industry

5.3.7. By Region