Global Fumed Silica market is anticipated to grow significantly through 2028 due to its increased demand from the adhesives & sealant sector. In 2020, the adhesive and sealants market value in Europe reached USD 18.38 billion.

Global Fumed Silica market is expected to expand during the projected period due to increasing demand from the adhesives & sealant sector as it is used to improve performance and durability. Substances that absorb another material are called fumed silica. Through the adhesion process, fumed silica builds layers on the surface.

They induce solids, liquids, and gases to lose some of their characteristics while keeping their chemical and physical characteristics, causing them to stick to their surfaces. Furthermore, the pharmaceutical industry’s growing need for polymeric fumed silica to remove antibiotics, peptides, proteins, and other chemicals is another factor anticipated to drive the expansion of the worldwide fumed silica market.

In addition, fumed silica is used as a reinforcing filler in silicone elastomers to enhance their mechanical properties. Silicone elastomers are extensively used in the automotive, construction, and electronics industries due to their excellent mechanical properties such as strength, toughness, and durability.

Browse over XX market data Figures spread through XX Pages and an in-depth TOC on the “Global Fumed Silica Market” @ https://www.techsciresearch.com/report/global-fumed-silica-market/2270.html

Along with this silicone elastomers are also used in a variety of products such as sportswear, footwear, voltage line insulators, medical devices, and implants. Therefore, the fumed silica market is expected to grow throughout the forecast period.

Increasing Demand from the Adhesives and Sealants Sector

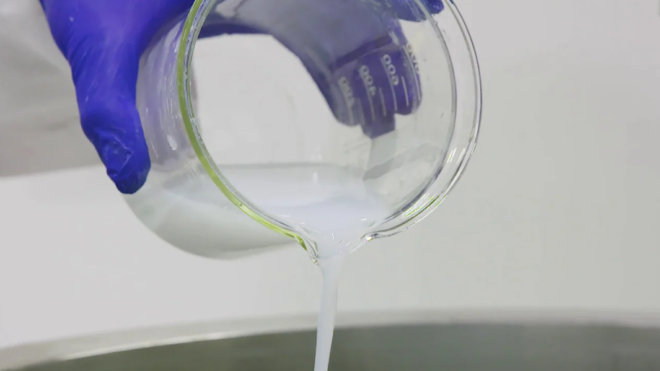

To raise the component’s viscosity, improve anti-settling capabilities during storage, manage extrusion properties during the application, and impart anti-sag properties during cure, fumed silica is utilized as a rheology control additive in the adhesive and sealant business. Compared to coated precipitated calcium carbonates (PCC), which are often used to regulate the rheology of Sewage Treatment Plants (STP) and polyurethane adhesives and sealants, treated fumed silica offers noticeably greater adhesive strength. Fumed silica has a lower specific gravity than calcium carbonate and contributes much less to adhesive weight, which might be advantageous in applications where adhesive weight is a problem, such as automobile lightweighting.

For instance, Henan Xunyu Chemical Co., Ltd. produced XYSIL fumed silica is widely used in all kinds of adhesive and sealant industries, such as silicone sealants, PVC-plastisol sealants, polyacrylate sealants, epoxy adhesives, polyurethane adhesive, unsaturated polyester, and polyurethane water-based adhesive.

Additionally, fumed silica aggregates are commonly used to improve the processing and performance characteristics of films formed from natural rubber, acrylates, polychloroprene, and many other water-based latex emulsions. These particles have a submicron size, and high-specific-surface-area which decreases drying times, mitigates crack formation by modulating the capillary pressure, and enhances the mechanical properties of the final product. Pre-dispersed fumed metal oxides provide an easy and effective tendency to pour which results in incorporating these particles into the adhesive films. Substantial enhancements have been observed in cohesive shear strength and thermo-mechanical properties of waterborne pressure-sensitive adhesives (PSAs) due to the fusion of highly dispersed fumed silica. Adhesive films with fumed silica content ranging from 0 to 15 weight % were created from water-based acrylic emulsions used for pressure-sensitive adhesive applications.

For instance, Cabot Corporation produced CAB-O-SIL fumed silicas having high surface area, surface chemistry, aggregated structure, and purity used in water-borne pressure-sensitive adhesives to improve their cohesive shear strength and thermo-mechanical properties.

Therefore, increasing demand for fumed silica from adhesive & sealant industries led to the growth of the Global Fumed Silica Market in the upcoming years.

Download Free Sample Report @ https://www.techsciresearch.com/sample-report.aspx?cid=2270

Customers can also request for 10% free customization on this report

Increasing Demand in the Pharmaceutical Industry

In the pharmaceutical industry, manufacturing tablets and capsules is a significant challenge, but fumed silica helps to enhance features, making the procedure noticeably simpler. Fumed silica is employed in the production of tablets as anticaking agents, adsorbents, disintegrants, and glidants to facilitate powder flow during tablet processing. These substances seem safe to biological organisms. It is regarded as generally safe by the FDA. Moreover, fumed silica can also be used as a thickening agent. In topical creams and ointments, fumed silica can increase the viscosity of the formulation, giving it a thicker and more consistent texture. This property helps to ensure that the medication stays on the skin for longer periods, providing more effective treatment.

For instance, Evonik produced AEROSIL & AEROPERL Pharma series fumed silica according to IPEC GMP guidelines for bulk pharmaceutical excipients.

Additionally, fumed silica is used as a thixotropic and anti-settling agent in paints and coatings to improve their rheological properties and prevent settling. The growing demand for high-quality and durable paints and coatings in these industries is expected to boost the demand for fumed silica.

For instance, Astrra Chemicals produces EROSIL- NV/200 XL 5M fumed silica work as an excellent lightweight filler which enhances the hardening of coating film, adhesion to surfaces, as well as reduces deterioration rate of the coatings and fading of materials with transparent top coating and diluent for all types of paints, dyes, inks, and pigments.

Thus, increasing demand for fumed silica from various end-user industries dominates the growth of the market in the projected period.

Hydrophilic Will Continue to Be a Key Type

Hydrophilic fumed silica is produced by hydrolyzing volatile chlorosilanes in an oxyhydrogen flame. In water, it may be completely absorbed and disseminated. This silica has exceptional insulating properties at high temperatures. Hydrophilic fumed silica might be advantageous for non-polar resin systems. It is used to thicken non-polar solvents like xylene, mineral spirits, and styrene and to reinforce silicone. It works well for compositions where shelf stability isn’t a major issue. Hydrophilic fumed silica is quickly being employed in various applications due to its low cost. It has great insulating qualities and exceptional chemical purity, even at high temperatures.

For instance, Cabot Corporation produced CAB-O-SIL and CAB-O-SPERSE hydrophilic fumed silica products which provide superior performance benefits for many types of applications.

Therefore, increasing demand for hydrophilic fumed silica for various applications anticipated the growth of the Global Fumed Silica market in the projected years.

Recent Developments

- In October 2021, Evonik recognized its new fumed silica plant in China in a joint venture with Wynca. The manufactured fumed silica is operated under the brand name AEROSIL.

- Wacker Chemie AG extended its fumed silica production facility with the opening of a new facility in Charleston in October 2019. For its HDK brand, the factory has a capacity of 13,000 metric tons per year.

- In September 2019, Cabot Corporation revealed the official beginning of its latest fumed silica manufacturing facility in Wuhai, Inner Mongolia, China

- In August 2019, Evonik Industries AG announced the expansion of fumed silica capacities in its plant at Antwerp Belgium for applications including coatings and paints, modern adhesive systems, transparent silicones, and non-flammable insulation material.

You may also read:

Egypt Ammonia Market Growth Outlook to 2028 Trends and Forecasts

United Kingdom Green Hydrogen Market Outlook 2024-2028 Size and Growth Prospects

Egypt Textiles Market Understanding Growth Drivers and Forecasts

Passenger Car Green Tire Market Share Analysis USD 104.6 Billion

Table of Content-Fumed Silica Market

- Product Overview

1.1. Market Definition

1.2. Scope of the Market

1.2.1. Markets Covered

1.2.2. Years Considered for Study

1.2.3. Key Market Segmentations

- Research Methodology

2.1. Objective of the Study

2.2. Baseline Methodology

2.3. Key Industry Partners

2.4. Major Association and Secondary Sources

2.5. Forecasting Methodology

2.6. Data Triangulation & Validation

2.7. Assumptions and Limitations

- Executive Summary

3.1. Overview of the Market

3.2. Overview of Key Market Segmentations

3.3. Overview of Key Market Players

3.4. Overview of Key Regions/Countries

3.5. Overview of Market Drivers, Challenges, Trends

- Voice of Customer

- Global Fumed Silica Market Outlook

5.1. Market Size & Forecast

5.1.1. By Value & Volume

5.2. Market Share & Forecast

5.2.1. By Type (Hydrophilic and Hydrophobic)

5.2.2. By Application (Coatings, Adhesives & Sealants, Pharmaceuticals, Others)

5.2.3. By Region (North America, Europe, Asia Pacific, South America, Middle East & Africa)

5.2.4. By Company (2022)

5.3. Market Map

5.3.1. By Type

5.3.2. By Application

5.3.3. By Region

- North America Fumed Silica Market Outlook

6.1. Market Size & Forecast

6.1.1. By Value & Volume

6.2. Market Share & Forecast

6.2.1. By Type

6.2.2. By Application

6.2.3. By Country

6.3. Pricing Analysis

6.4. North America: Country Analysis

6.4.1. United States Fumed Silica Market Outlook

6.4.1.1. Market Size & Forecast

6.4.1.1.1. By Value & Volume

6.4.1.2. Market Share & Forecast

6.4.1.2.1. By Type

6.4.1.2.2. By Application

6.4.2. Mexico Fumed Silica Market Outlook

6.4.2.1. Market Size & Forecast

6.4.2.1.1. By Value & Volume

6.4.2.2. Market Share & Forecast

6.4.2.2.1. By Type

6.4.2.2.2. By Application

6.4.3. Canada Fumed Silica Market Outlook

6.4.3.1. Market Size & Forecast

6.4.3.1.1. By Value & Volume

6.4.3.2. Market Share & Forecast

6.4.3.2.1. By Type

6.4.3.2.2. By Application