The Global Subsea Flowlines Market is expected to grow during the forecast period (2025-2029) driven by the rising offshore oil and gas exploration and production activities, particularly in deepwater and ultra-deepwater fields.

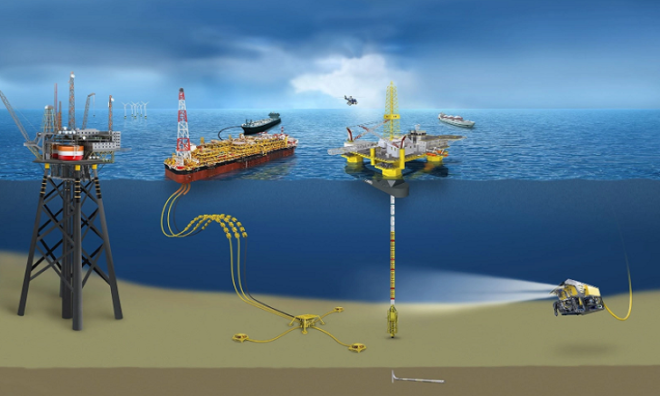

According to TechSci Research report, “Subsea Flowlines Market – Global Industry Size, Share, Trends, Opportunity, and Forecast 2029F”, Global Subsea Flowlines Market was valued at USD 10.4 Billion in 2023 and is anticipated to project robust growth in the forecast period with a CAGR of 7.1% through 2029. The Global Subsea Flowlines Market is the increasing adoption of Floating Production Storage and Offloading (FPSO) units and subsea tieback systems. FPSOs serve as versatile offshore production facilities that can be deployed in remote and deepwater locations where traditional fixed platforms are economically impractical. These units require robust subsea flowline networks to connect subsea wells to the FPSO, enabling the efficient transfer of hydrocarbons for processing and storage.

FPSOs offer several advantages, including reduced time to first oil, operational flexibility, and lower environmental impact compared to fixed-platform installations. Subsea tiebacks, on the other hand, involve connecting new subsea wells to existing production facilities, typically via flowlines, to maximize the utilization of existing infrastructure and extend field life. Both FPSOs and subsea tiebacks drive demand for advanced subsea flowline solutions that can accommodate varying production rates, reservoir conditions, and seabed topographies.

The growth in FPSO installations is particularly pronounced in regions such as offshore Brazil, West Africa, and Southeast Asia, where deepwater discoveries continue to drive offshore development activities. As operators seek to monetize offshore reserves efficiently, the demand for reliable and cost-effective subsea flowline systems capable of supporting FPSO operations remains strong. Advances in flowline technology, including the use of composite materials for risers and corrosion-resistant alloys for pipelines, are critical in meeting the stringent operational requirements of FPSOs and subsea tiebacks.

Browse over XX market data Figures spread through XX Pages and an in-depth TOC on the “Global Subsea Flowlines Market”

https://www.techsciresearch.com/report/subsea-flowlines-market/24362.html

Based on Type, the Global Subsea Flowlines Market saw the Medium Pressure segment dominated and is expected to maintain its leadership through the forecast period. Medium pressure subsea flowlines are crucial components in offshore oil and gas production systems, typically designed to withstand pressures ranging from 1,500 to 5,000 psi. These flowlines are employed in a wide range of subsea applications, including connecting subsea wells to production facilities or processing hubs. The dominance of the Medium Pressure segment can be attributed to several factors.

Firstly, medium pressure flowlines are versatile, capable of handling a broad spectrum of reservoir conditions and production scenarios, making them suitable for both shallow and deepwater operations. They offer a balanced approach, providing adequate pressure capacity without the complexities and costs associated with high-pressure systems.

Secondly, advancements in subsea engineering and materials science have enabled the development of reliable medium pressure flowline solutions that optimize production efficiency and mitigate operational risks. Thirdly, the geographic distribution of offshore oil and gas reserves, particularly in regions like the Gulf of Mexico, North Sea, and offshore Brazil, where medium pressure conditions are prevalent, drives sustained demand for these flowline systems.

Additionally, medium pressure flowlines align well with industry trends towards cost optimization and operational efficiency, as they offer a favorable balance between performance requirements and capital expenditure. As offshore developments continue to expand into deeper and more challenging environments, the versatility and reliability of medium pressure subsea flowlines position this segment to maintain its dominance in the Global Subsea Flowlines Market, catering to the evolving needs of the oil and gas industry for secure and efficient hydrocarbon extraction solutions.

Based on region, The Asia Pacific region is experiencing rapid growth in the Global Subsea Flowlines Market due to several key factors that position it as a pivotal area for offshore oil and gas development. Asia Pacific hosts a significant number of offshore oil and gas fields, particularly in countries like Australia, Malaysia, and Indonesia, where there are extensive deepwater and ultra-deepwater reserves. The exploration and production activities in these regions necessitate the installation of sophisticated subsea flowline systems to transport hydrocarbons from seabed wells to processing facilities or offshore platforms efficiently. The increasing energy demand from rapidly developing economies in Asia Pacific is driving investments in offshore oil and gas infrastructure.

Countries such as China and India are expanding their energy portfolios to meet growing domestic consumption, leading to heightened exploration and production activities in offshore basins. Subsea flowlines play a crucial role in enabling these nations to harness their offshore reserves and enhance energy security. Technological advancements in subsea engineering and manufacturing capabilities in Asia Pacific are supporting the region’s growth in the subsea flowlines market. Local companies are increasingly involved in the design, fabrication, and installation of subsea infrastructure, leveraging innovative solutions such as advanced materials for flowlines and enhanced installation techniques.

This indigenous capability reduces dependency on international suppliers and enhances project execution efficiency. Supportive government policies and regulatory frameworks in Asia Pacific facilitate offshore oil and gas developments by providing conducive environments for investment and operations. Regulatory stability, coupled with initiatives to streamline project approvals and environmental regulations, encourages both domestic and international oil and gas companies to pursue offshore projects in the region.

The deployment of floating production systems (FPSOs) and floating liquefied natural gas (FLNG) facilities in Asia Pacific further drives the demand for subsea flowlines. These offshore installations require robust flowline solutions to connect subsea wells to floating production units, enabling efficient hydrocarbon production and export. Asia Pacific region’s dynamic energy landscape, abundant offshore reserves, technological prowess, supportive regulatory environment, and increasing adoption of FPSOs and FLNG facilities collectively contribute to its status as the fastest-growing region in the Global Subsea Flowlines Market. As the region continues to invest in offshore exploration and production capabilities, the demand for advanced subsea flowline solutions is expected to grow, further solidifying its position as a key player in the global offshore energy sector.

Key market players in the global Subsea Flowlines market are: –

- TechnipFMC plc

- Saipem S.p.A.

- Subsea 7 S.A

- McDermott International Ltd.

- Aker Solutions ASA

- Oceaneering International Inc.

- Prysmian S.p.A

- Baker Hughes Company

- Siemens SA

- Tenaris S.A

- Weatherford International Plc

- MODEC Inc.

Download Free Sample Report

https://www.techsciresearch.com/sample-report.aspx?cid=24362

Customers can also request for 10% free customization on this report.

“The Global Subsea Flowlines Market presents significant opportunities driven by expanding offshore exploration and production activities worldwide. One key opportunity lies in the development of deepwater and ultra-deepwater fields, where robust subsea flowline systems are essential for transporting hydrocarbons efficiently over long distances to production facilities or floating platforms. Technological advancements, such as the use of composite materials for flexible risers and advanced welding techniques for steel flowlines, offer opportunities to enhance reliability and reduce maintenance costs.

The growing adoption of floating production systems (FPSOs) and floating liquefied natural gas (FLNG) facilities presents another avenue for market growth. These offshore installations require specialized subsea flowlines to connect subsea wells to floating production units, supporting the monetization of stranded offshore reserves.

Additionally, the trend towards digitalization and automation in subsea operations opens opportunities for integrating smart sensors and monitoring systems into flowline networks, enabling real-time data analytics and predictive maintenance strategies to optimize operational efficiency and reduce downtime”, said Mr. Karan Chechi, Research Director of TechSci Research, a research-based global management consulting firm.

“Subsea Flowlines Market – Global Industry Size, Share, Trends, Opportunity, and Forecast, Segmented By Type (Low Pressure, Medium Pressure), By Application (Shallow Water, Deepwater), By Region & Competition 2019-2029F”, has evaluated the future growth potential of Global Subsea Flowlines Marketand provides statistics & information on market size, structure, and future market growth. The report intends to provide cutting-edge market intelligence and help decision makers take sound investment decisions. Besides the report also identifies and analyzes the emerging trends along with essential drivers, challenges, and opportunities in Global Subsea Flowlines Market.

Contact

TechSci Research LLC

420 Lexington Avenue,

Suite 300, New York,

United States- 10170

M: +13322586602

Email: [email protected]

Website: https://www.techsciresearch.com